Product Detail

Specification of Cold Rolled Aluminum Circle

Alloy |

1050,1060,1200,1100,1070,3003,5005,5052,etc |

| Thickness | <5 mm |

| Diameter | >70 mm |

| Temper | O,H12,H14,H16,H18,H22,H24 |

| Surface | Mill finish, coated, polished, embossed, etc |

| Application | Lamps, cookware, kitchen,utensils, lampshades, aluminum pots, electric heating pot thermal insulation chassis, rice cooker liner, smokeless pot, non-stick pan, aluminum bottle, etc |

| MOQ | 5 Tons |

| Packaging | wooden case |

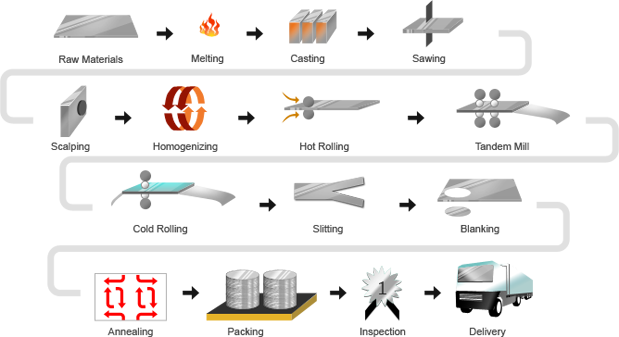

Cold rolling production process:

Using hot-rolled steel coil as raw material, the oxidized skin was removed by acid washing, and then cold-rolling, the finished product is rolled hard coil. Cold work hardening due to continuous cold deformation increases the strength and hardness of the rolled hard coil and decreases the toughness index., therefore, the punching performance will deteriorate and can only be used for parts that are simply deformed. Rolled hard rolls can be used as raw materials for hot-dip galvanizing plants because the hot-dip galvanizing units are provided with an annealing line. The rolled hard coil weight is generally 6 ~13.5 tons, and the hot-rolled pickling coils are rolled continuously at room temperature.

Product Features of Cold Rolled Aluminum Circle:

Because it is not annealed, its hardness is very high (HRB is greater than 90), and the machining performance is extremely poor. Only a simple directional bending process of less than 90 degrees can be performed(perpendicular to the winding direction).

To put it simply, cold rolling is made on the basis of hot rolled rolls. Generally speaking, the produce process is hot rolling-pickling-cold rolling.

Cold-rolled aluminum Circle can be used in automobiles, rice cookers, washing machines, etc household appliances, as well as industrial equipment, construction materials.

Product Process

Ingot/Master Alloys --- Melting Furnace – Holding Furnace --- D.C. Caster --- Slab ---- Scalper --- Hot Rolling Mill – Cold Rolling Mill – Punching – Annealing Furnace -- Final Inspection – Packing --- Delivery

Packaging & Delivery

| Packaging Details: | Packing: export standard, covering with brown paper and plastic film then packed with wooden case/palletPacking: export standard, covering with brown paper and plastic film then packed with wooden case/pallet such 2-3 tonnes in 1 wooden pallet. Such 18-22 tonnes in 1x20' container. |

|---|---|

| Delivery Detail: | Within 30 days |